Constant temperature and humidity test chamber

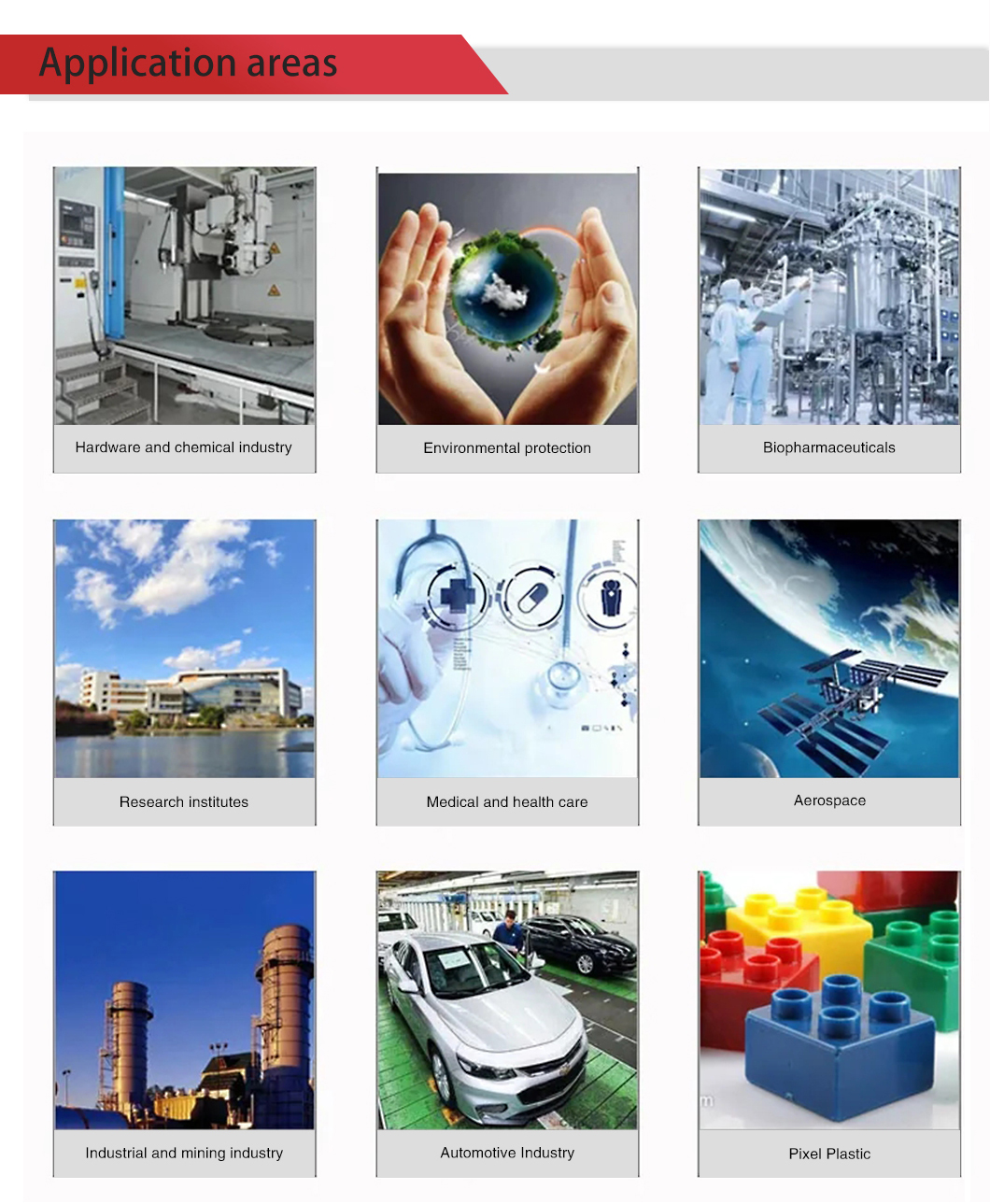

The high and low temperature alternating wet heat test machine is also known as the environmental test machine, which tests the thermal resistance, cold resistance, dry resistance and moisture resistance of various materials. It is suitable for testing the quality of electronic, electrical, communication, instrumentation, vehicle, plastic products, metal, food, chemical, building materials, medical, aerospace and other products.

Product Details

Constant temperature and humidity test chamber

◆ scope of application

The constant temperature and humidity test chamber, also known as an environmental test chamber, is a device used to evaluate the performance of materials under various environmental conditions. It can test the heat resistance, cold resistance, dryness resistance, and moisture resistance of different materials. This equipment is widely used in industries such as electronics, electrical appliances, mobile phones, communications, instruments, vehicles, plastic products, metals, food, chemicals, building materials, medical, and aerospace, to ensure product quality.

◆ Product features

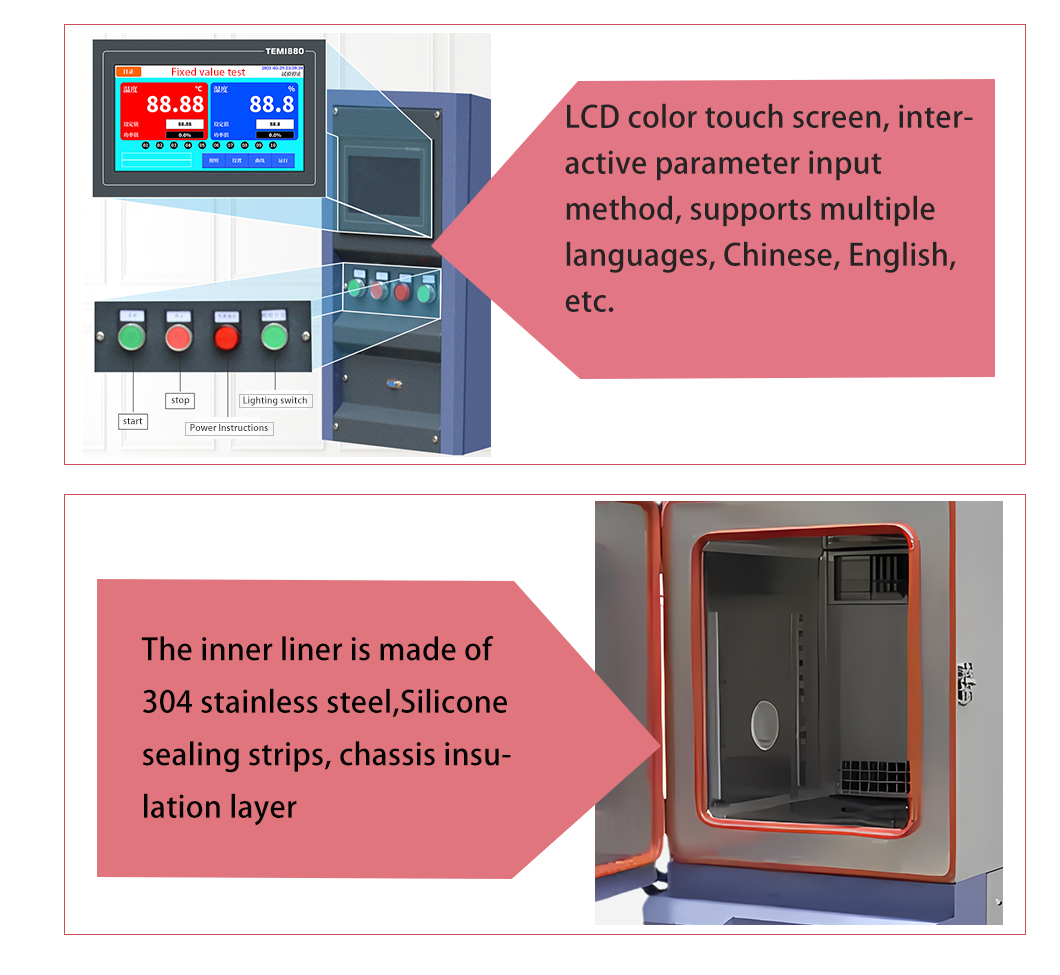

● The controller adopts imported LCD display screen, which can display the measured value, set value and time at the same time.

● The controller has multi-segment program editing and temperature and humidity can be controlled quickly (OUICK) or slope (SLOP).

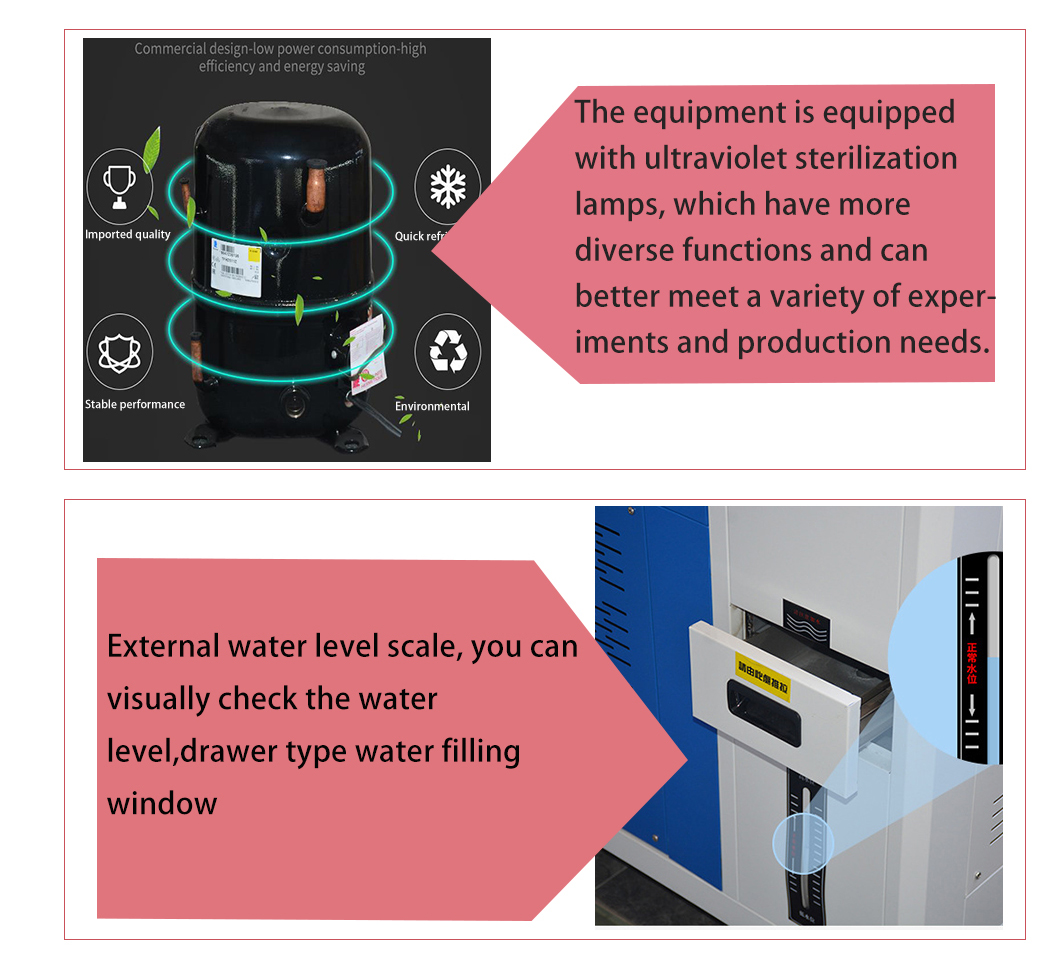

● It has an external water supply system, which is convenient for replenishing water for the humidification tank and automatic recovery and use.

● The outer box is cold-rolled high-quality steel plate with spray paint, and the surface is phosphated and sprayed plastic treatment. The inner box is SUS304# stainless steel 1.2mm

● The compressor circulation system adopts the French "Tecsun" brand, which can effectively remove the lubricating oil between the condenser tube and capillary tube, and the whole series adopts environmental refrigerant (R23, R404)

● Reliable grounding protection device, leakage/circuit breaker protection, heater short circuit protection, blower motor overload protection, independent overtemperature alarm of the working room, refrigeration machine overpressure protection, refrigeration machine overload protection, power undervoltage, overvoltage, phase loss protection.

|

product name |

Constant temperature and humidity test chamber |

|||||||||||||

|

Product model |

MRT-HWHS-50 |

MRT-HWHS-100 |

MRT-HWHS-150 |

MRT-HWHS-225 |

MRT-HWHS-504 |

MRT-HWHS-800 |

MRT-HWHS-1000 |

|||||||

|

Inner size (D*W*H) mm |

350*350*410 |

400*500*500 |

500*500*600 |

500*600*750 |

700*800*900 |

800*1000*1000 |

1000*1000*1000 |

|||||||

|

External dimensions (D*W*H) mm |

850*800*1600 |

850*900*1700 |

1000*1050*1800 |

1000*1100*1800 |

1200*1750*2000 |

1300*1500*2000 |

1500*1500*2000 |

|||||||

|

Temperature range |

A:-20℃~+150℃ B:-40℃~+150℃ C:-60℃~+150℃ D:-80℃~+150℃ |

|||||||||||||

|

Power (W) |

3KW |

4KW |

5KW |

6KW |

7KW |

8KW |

9KW |

|||||||

|

Volume (L) |

50L |

100L |

150L |

225L |

504L |

800L |

1000L |

|||||||

|

Supply voltage |

AC220V±10% 50~60HZ |

AC380V±10% 50~60HZ |

||||||||||||

|

Humidity range |

20%~98%RH (10%~98% RH/5%~98%RH are special selection conditions) |

|||||||||||||

|

Humidity uniformity |

± 2.0%RH (humidity> 75%RH), ± 3.0%RH (humidity ≤ 75%RH) |

|||||||||||||

|

Humidity accuracy |

±0.1%RH |

|||||||||||||

|

Temperature accuracy |

±0.1℃ |

|||||||||||||

|

Temperature fluctuation |

±0.5℃ |

|||||||||||||

|

Temperature uniformity |

±2℃ |

|||||||||||||

|

Ambient temperature |

-5℃~35℃ |

|||||||||||||

|

Human-machine interface/controller |

7-inch color touch interface and high performance programmable controller |

|||||||||||||

|

Heating/cooling time |

Heating rate: 1℃~3℃/min, cooling rate 0.7℃~1℃/min, (special heating and cooling rate can be customized) |

|||||||||||||

|

Compression engine |

France "Taikang" and Germany "GEA blog" Germany "Bizer" |

|||||||||||||

|

Tank volume |

15L/30L |

|||||||||||||

|

Water replenishment method |

Manual water refill / automatic water refill |

|||||||||||||

|

Net weight (kg) (approx.) |

220KG |

280KG |

320KG |

360KG |

550KG |

630KG |

680KG |

|||||||

|

Gross weight (kg) (approx.) |

240KG |

300KG |

350KG |

390KG |

570KG |

660KG |

710KG |

|||||||

◆ technical parameter